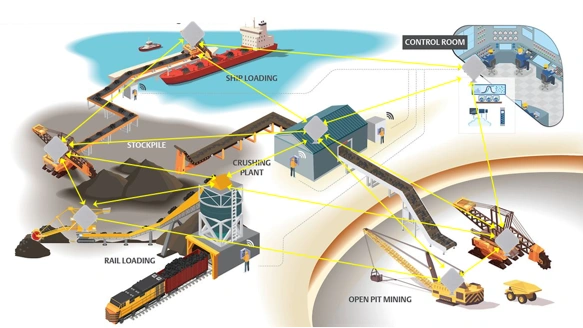

The vast amount of data generated in mining operations—such as video and voice communications, along with vehicle telemetry requires high-speed digital networks to enhance efficiency and cut costs.

Wireless communication system is vital for open-pit mining operations, as it effectively addresses the challenges posed by the complexity and geographical constraints of underground environments.

Wireless mining mesh communication networks provide essential data, voice, and video services, supporting applications crucial for safe and efficient mining operations. These networks support the transmission of data, voice, and video, which are crucial for both mobile operations (such as stackers, reclaimers, wagon loaders, and mobile excavators) and fixed applications used for material loading and unloading. Our Public Address (PA) system facilitates communication with employees and visitors in noisy environments, enabling clear instructions, warnings, and announcements. Additionally, our CCTV surveillance system employs cameras to monitor facilities and detect suspicious activities, enhancing security. The Paddle Feeder communication system ensures a smooth, uninterrupted flow of material by maintaining reliable communication between the paddle feeder and the control system.

Brij System Ltd provide industrial wireless mesh networks bring mission-critical connectivity to underground mines and tunnels are some of the most challenging environments.

in which to deploy network systems. Connectivity and throughput demands are high, but circular ramps and declines, stopes, and mine layout place limitations on how far wireless signals can travel. Many mines, therefore, depend on fiber to achieve reliable underground communications, but installing fiber in active drives, panels and declines is difficult to schedule and can create operational and maintenance nightmares.

In addition, development and drill and blast areas can rarely support any fiber infrastructure. It is not uncommon for trucks to accidentally catch and rip down sections of fiber and when that happens connectivity across the entire underground mine can be lost.

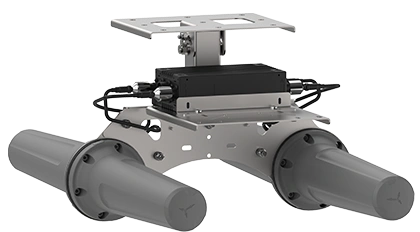

Brij System Ltd provides a robust alternative to fiber and traditional single radio wireless systems using multi-radio, multi-frequency nodes combined with the Poynting wide-band, bi-directional, circular polarized antenna system. Wireless radio maintain multiple simultaneous connections between peers for inherent redundancy and can simultaneously send and receive information on different frequencies, mitigating issues due to interference, congestion, and equipment outages.

This also increases transceiver capacity to ensure low latency and enables mines to cascade radio together as many as 10 hops or more without throughput degradation. Poynting antennas provide bi-directional coverage with dual-frequency Wi-Fi connections to assist in propagating signals around tunnel bends and to and from moving machinery. Together they create a complete underground and tunnel- wide wireless network for mission-critical data, video, and voice communications. The system can also be used to supplement existing fiber and cable “hot spot” networks, provided via vertical shaft access levels, portals and tunnels.

In the challenging and harsh environments of port seashore facilities, Mining industry loading plants, Steel Plants RMHS Area, Power Plant CHP Area, and cement plants, where extreme climate conditions such as high humidity and harsh weather prevail, managing vital machinery efficiently is crucial. A critical application involves the sophisticated remote control and interlocking of key mobile machines used in material handling. These include:

Essential for bulk material handling and storage.

Used for feeding material with precise control.

Vital for container stacking and retrieval.

Critical for loading and unloading cargo from ships.

These machines, integral to the material handling section, require robust and reliable remote control systems and interlocking mechanisms to ensure operational efficiency, safety, and accuracy. The remote control and interlocking systems must be resilient to environmental challenges, providing precise management and coordination of these vital machines to maintain smooth and continuous operations.

The solution came from Brij System wireless devices to establish a wireless link—whether point-to-point (PTP), point-to-multipoint (PTM), or a mesh network—between the mobile machines and a protocol converter module located in the Control Room or Load Center. This innovative setup facilitated seamless data communication between two PLC systems. From this point, the connection was further extended via an additional protocol converter module, ultimately linking to a PLC in the Central Control Room (CCR) through a robust wireless or fiber optic connection.